2Quality Assurance System

2.1 Quality Control in Manufacturing Processes

2.2 Control of Standards and Measuring Equipment

2.1 Quality Control in Manufacturing Processes

We consider that the quality control in manufacturing processes is most important to provide semiconductor products with the high quality and high reliability required by our customers.

For this purpose, we define the control conditions based on various technical information from our Engineering and Development Division in the Control Process Charts, document them, and conduct the individual manufacturing operations using them. The Control Process Charts mean the systematized process flows in which the equipment to be used, the materials to be used, individual quality control parameters, control standards, and inspection standards are described.

Semiconductor manufacturing consists of two main processes: the wafer process (front-end process) and the assembly process (back-end process). Below are example process flowcharts of our typical product.

_en.png)

_en.png)

2.2 Control of Standards and Measuring Equipment

1) Control of Standards

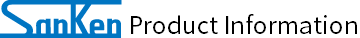

To maintain the quality and reliability of our products, we have established our product quality management system, i.e., the documented quality system where control regulations, control standards, and manufacturing standards and procedures are hierarchically organized with the quality manuals being at the top of the hierarchy. The above standards are instituted as systematized standards.

Below is the chart describing our standard system:

Standard System Chart

2) Control of Measuring Equipment

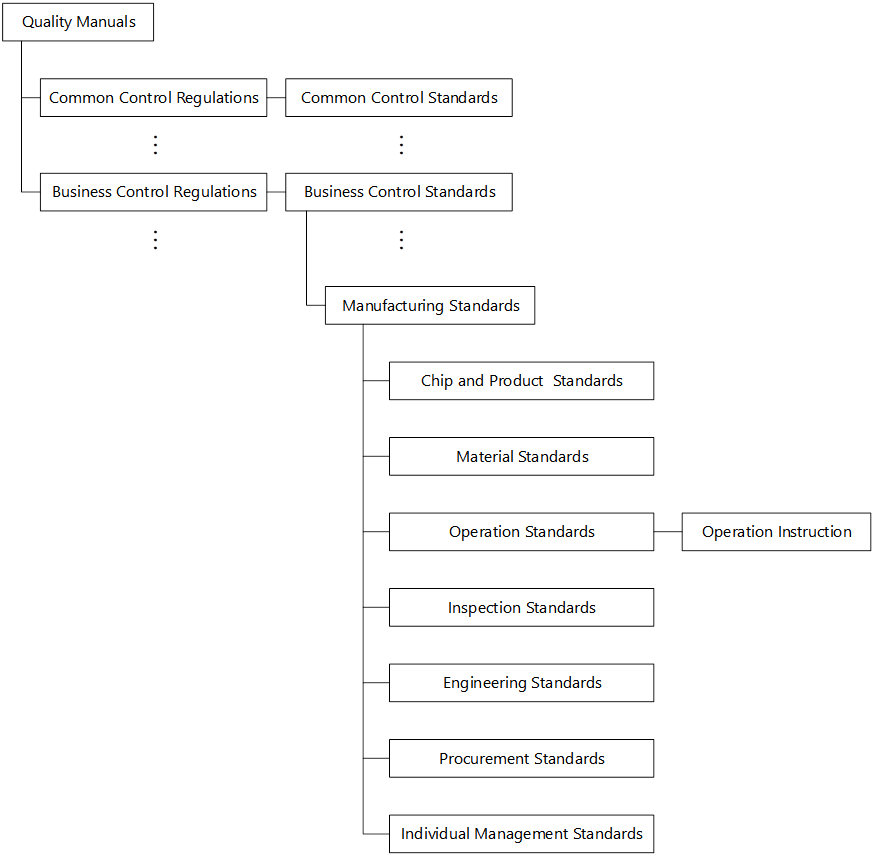

The qualities of the measuring equipment used for measuring electrical and optical characteristics of semiconductors can be ensured and improved by maintaining the equipment in a normal condition constantly and by allowing them to operate within the required accuracy levels. We have established the “Standards on Measuring Equipment Control and Operation” in our in-house regulations, which are confirmed that our traceability to the national standards is firmly established, and implemented regular inspections and calibrations at in-house or external calibration organizations.

Below is the chart showing our traceability system for the measuring equipment.

Traceability System Chart for Measuring Equipment

2.3 Product Traceability

We control the traceability of the products shipped to our customers so that their manufacturing histories can be traced by each marking on the product body, i.e., the part number and lot number.

Below is an example of the lot number marked on our product. For more details, please refer to the data sheet of each product. In addition, you can confirm the manufacturing history from packing conditions: the labels attached on shipping boxes also indicate the part numbers and lot numbers of the products being packed. (Please note that some products are excluded from this system.)

Example Marking of Lot Number

_en.png)

2.4 Customer Complaint Management

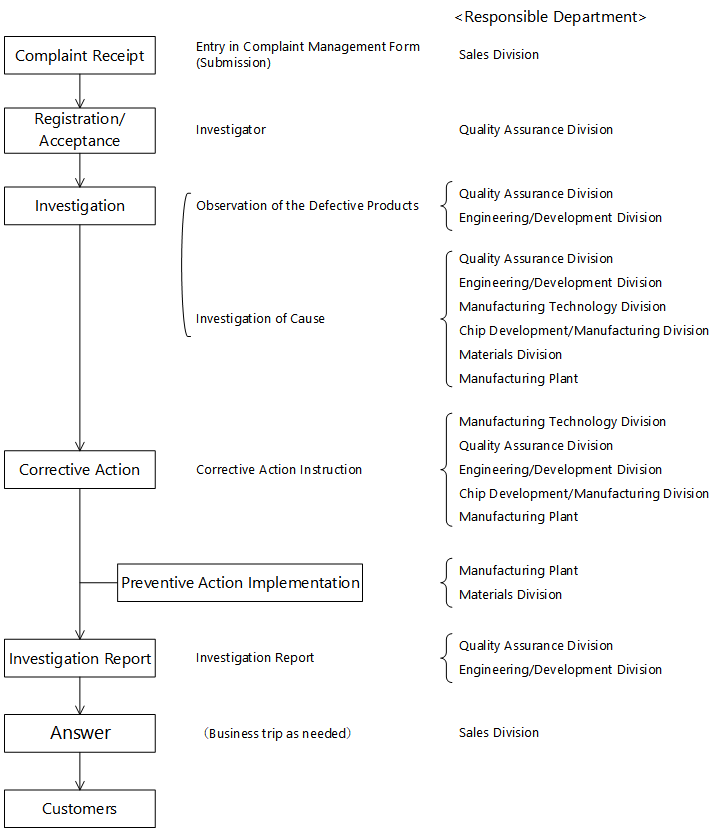

If any failure is found out from our products used in customer’s equipment, we will handle it according to the complaint management flowchart shown below.

Firstly, our Sales Division or authorized distributors will receive any complaints or returns from customers. The sales person who received a complaint then inputs its related information (incl. failure details, part number, user name, date received, set name, defect rate, lot) into the complaint management form of our electronic processing system, and informs our Quality Assurance Division of the complaint.

After that, the returned product is passed over to our Quality Assurance Division.

Based on the complaint management form, our Quality Assurance Division tries to grasp what state the failure is in and identify the cause from analytical investigation results on the returned product. According to the cause identified, they will determine what actions to take.

Subsequently, these analytical investigation results are fed back to our Engineering and Development Division and relevant manufacturing process operators on an as-needed basis. This is how we maintain and improve our reliability and how we attempt to prevent a reoccurrence of the failure.

We also report the progress of such investigation to the customer who sent the complaint as a “Complaint Investigation Report” through our Sales Division.

Complaint Management Flowchart

2.5 Approaches to Quality-related Standards

Please see the “ISO-Related Data” page on the Sanken Electric Corporate website.

Questions or Comments?

Please feel free to contact us if you cannot find the desired product from the lineup.