Special Feature: Digital Power supply

What Is a Digital Power Supply? Sanken’s Digital Power Management ICs: “MD67xx Series”

Contents

- From Analog to Digital—a Trend toward Shifting Control Methods in Switching Power Supplies

- What Is a Digital Power Supply?

- Benefits from Digitizing a Power Supply

From Analog to Digital—a Trend toward Shifting Control Methods in Switching Power Supplies

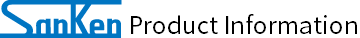

Demands for Energy Loss Reduction in Switching Power Supplies

Switching power supplies (AC/DC or DC/DC) are indispensable to any equipment, regardless of fields to which they belong, e.g. industrial, consumer, or automotive use.

One of the requirements a switching power supply should meet is how efficiently and stably convert supplied electricity to the power that a load needs. As global warming and energy issues have emerged as urgent challenges recently, more and more manufacturers today are seeking the technologies to minimize energy losses in power supplies.

From Conventional “Analog Control” to New Approach “Digital Control”

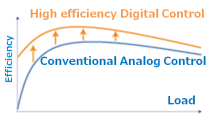

In conventional switching power supplies, it used to be common to employ analog control methods to stabilize output voltage. Analog control power supplies have evolved together with improvements in load responsiveness and power supply efficiency achieved by various innovations, e.g., phase compensation with error amplifier characteristics and dynamic operation mode change at light load.

On the other hand, the more severe the energy issues have become, the more the calls to have power supplies adopt digital control technologies as a new way to achieve high efficiency.

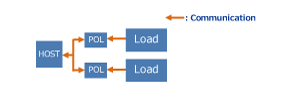

Digital control power supplies can control converters with a new topology that was almost unachievable to conventional analog control power supplies. Also, they have a great advantage that an optimal operating or control method is appropriately switched according to conditions via communications between a host or load side.

However, controlling a digital power supply requires a very quick response because it has to control electric circuits where a powerful and expensive DSP (Digital Signal Processor) is still essential.

Sanken’s Digital Power Management ICs: “MD67xx Series”

p>Sanken Electric has developed the MD67xx series, integrating an 8-bit MCU (Microcontroller Unit) suitable for digital power supply control and an analog driver IC into one device.The digital power management IC (MD6603) built in the MD67xx series is our own compact, low-powered, digital-control-function-rich MCU that will help you easily design a digital power supply system.

MD6750 series won the Minister of Economy, Trade and Industry Award (Power-saving Field), as the highest award in the Product & Business Model Category at the FY2022 Energy Conservation Grand Prize sponsored by the Energy Conservation Center, Japan (ECCJ; supported by the Ministry of Economy, Trade and Industry).

Related Article: Winner of the Energy Conservation Grand Prize: Sanken’s High-efficient Digital Power Management ICs [MD6750 Series]

Browse Products List Digital Power Management ICs

Digital Power Management ICs

What Is a Digital Power Supply?

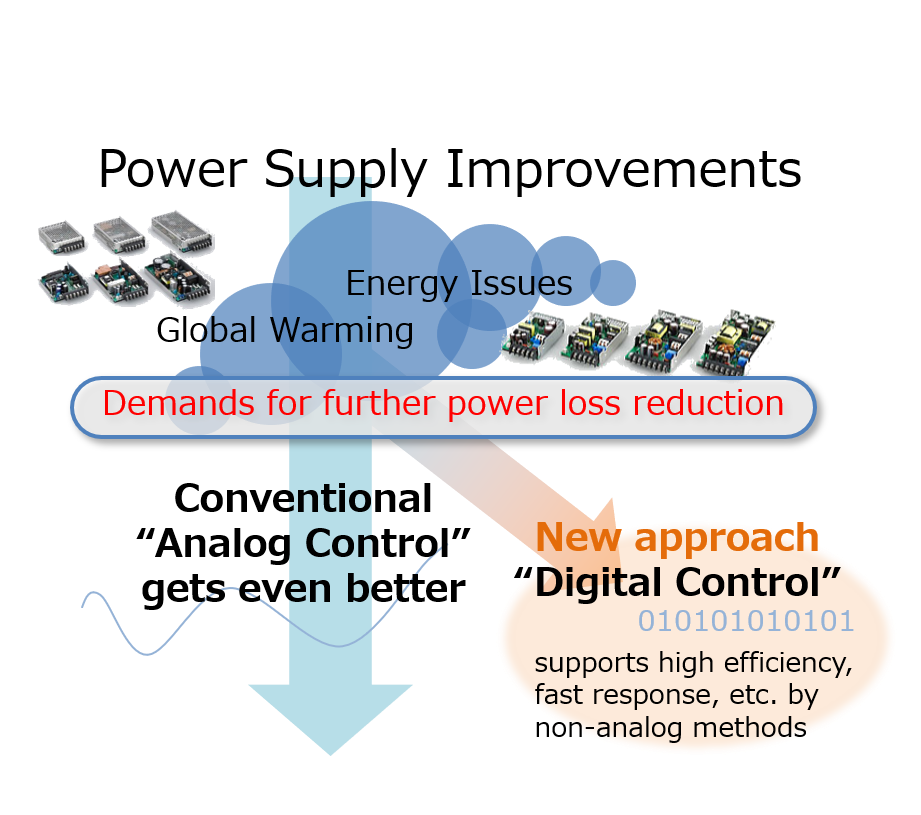

Conventional Analog Control Power Supplies

A conventional analog control power supply, for example, consists of a feedback control circuit where an error amplifier applies phase compensation to an output-vs-reference voltage difference and adjusts a PWM waveform duty cycle that turns on/off a power MOSFET inside a converter (see the left side of the diagram).

This type of power supply is inexpensive but has the following technical challenges:

- More abnormality detection functions mean more circuits to be used

- Limited in diversifying converter topologies to improve efficiency

- Difficult to lower output voltage due to limitations in reference voltage of error amplifiers

- Need to replace passive elements to support a wide range of products

- Need additional microcontrollers to add more functions like communication or operation logging

In contrast, a digital control power supply can perform the phase compensation by DSP-based numerical operation processing (i.e., digital filter) in which an error amplifier is conventionally used in analog control methods (see the right side of the diagram).

Digital Power Supplies

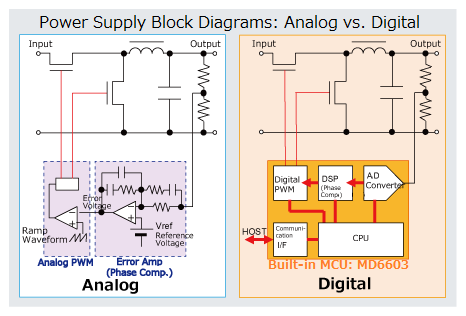

How does a digital power supply perform its DSP-based numerical operation processing to apply phase compensation? This section introduces the flow of digital control.

Digital Control Flow

[Ⅰ] Reads and digitizes the output voltage to be fed back with the AD converter

↓

[Ⅱ] Calculates a DSP-based phase compensation factor to determine a necessary PWM duty cycle

↓

[Ⅲ] Outputs a PWM waveform according to the duty cycle determined in Step [Ⅱ]

Moreover, a digital logic circuit generates the PWM waveform determined in Step [Ⅲ]. If the resolution of a specifiable duty cycle or cycle is not high enough, the output voltage may ripple. So, please be sure to use a high-resolution PWM that can generate a smooth and precise duty cycle or cycle.

Then, the digital control repeats these processes at a certain control cycle. In most cases, the digital control is synchronous with a PWM carrier cycle.

As explained above, the digital control is capable of carrying out such per-cycle active processing, which is incompetent to any analog control, thus allowing more advanced control technologies to be adopted.

You will need the following to control a digital power supply.

Typical devices required for feedback control:

- High-speed and high-precision AD converter

- High-speed computing DSP

- High-resolution PWM capable of setting smooth duty cycles or cycles

- Comparator and operational amplifier for overcurrent detection etc.

Various intelligent or communications processing:

- CPU

- Communications function

- Writable flash memory to store CPU programs

We can now offer the MD67xx series with all the requisites for digital power supplies.

Browse Products List Digital Power Management ICs

Digital Power Management ICs

Benefits from Digitizing a Power Supply

Adopting digital control methods to power supply systems will benefit a lot.

Let’s take a close look at what trade-offs you should consider bringing out the benefits ideal to your application through power supply digitization.

|

1. High Efficiency

|

2. Fast Responsiveness

|

|

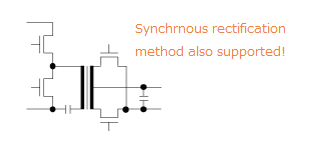

3. Various Converter Topologies Available

|

4. High Reliability

|

|

5. Various Device Types Available

|

6. Compactness

|

|

7. Low Voltage and High Current

|

8. Intelligence (Communication Function etc.) function)

|

Digital Power Management ICs: MD67xx Series Product Page / Inquiry Form

Digital Power Management ICs: Product List Click Here

Click Here

Please ask any questions using our inquiry form.

Questions or Comments?

Please feel free to contact us if you cannot find the desired product from the lineup.