What Is a Motor Driver?

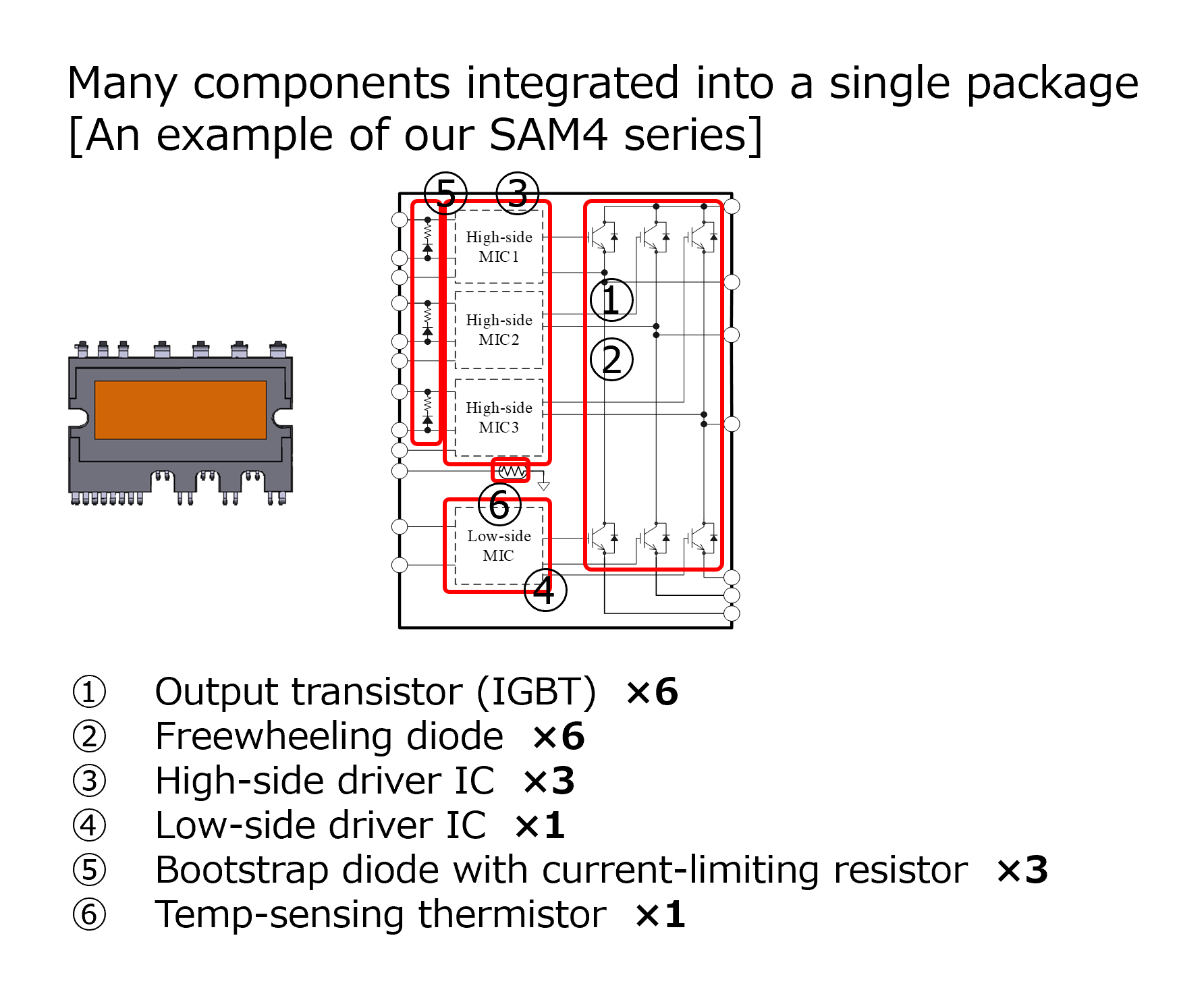

What Is a Motor?

The word “motor“ comes from a Latin word, “movere“, which means to move and give motion.

A motor is a device that gives motion and moves things without human or animal power, and converts various energy, such as electricity, steam, gasoline, and other energy, into mechanical motion.

An electric motor especially, which converts electrical energy into mechanical energy for use as power, is often simply referred to as a motor.

An electric motor is referred to as a motor in the rest of this page.

Now, a motor is used everywhere and is essential in our everyday lives.

A motor is used in a wide range of applications such as smartphones, game controllers, PCs, air conditioners, automobiles, manufacturing equipment, and infrastructure facilities, ranging from palm-sized to large-sized devices with several meters long.

Motors are also used to vibrate, to spin fans, and to work arms, rails, pumps, and compressors.

How Does a Motor Work?

How does a motor change electrical energy to kinetic energy?

Most motors work on the principle of magnetism, in which the S-pole and the N-pole are attracted to each other.

Electromagnets are essential to explain motors.

An electromagnet is a type of magnet in which the magnetic field is generated by current, which is to say, running electricity through an electromagnet makes it a magnet.

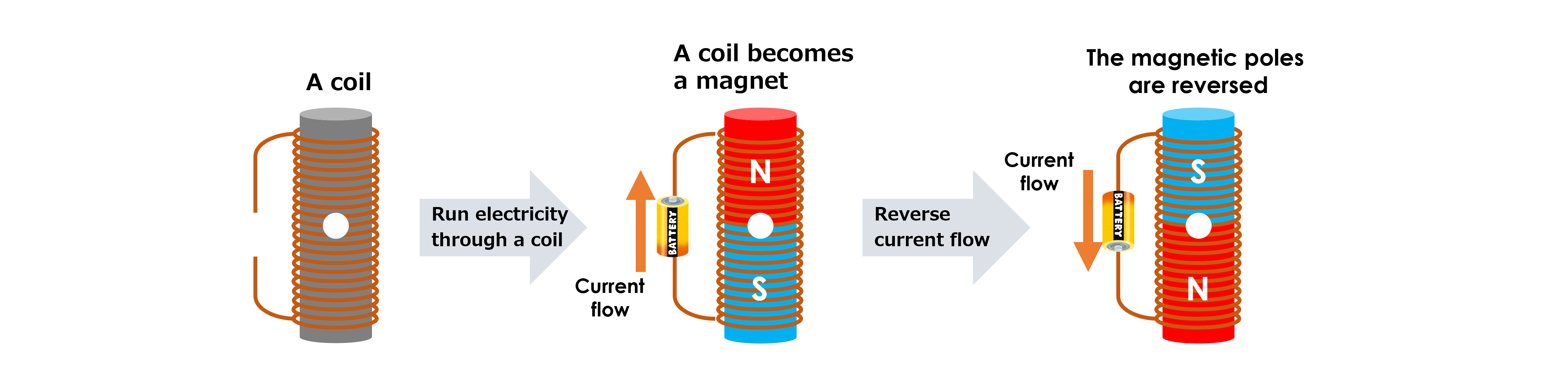

As shown in the figure below, an electromagnet consists of an iron core (magnetic core) wound helically by a coil. Some coils have no internal iron core, but coils described in the rest of this page refer to those with an internal iron core.

When a current is passed through the coil, a magnetic field is generated, and then the coil becomes a magnet.

Changing the direction of the current in the coil reverses the magnetic poles of the coil.

In this way, electromagnets only become magnets when needed by turning electricity on and off, and they also allow the direction of the current to change the direction of the magnetic poles.

Electromagnetic Properties

The figure below shows an overview of one example of a motor.

Most motors have internal permanent magnets and electromagnets.

Permanent magnets are installed around the coil. When current flows through the coil, the N-pole of the coil is attracted to the S-pole of the permanent magnet, and the S-pole of the coil is attracted to the N-pole of the permanent magnet, respectively.

If the direction of the current in the coil is changed, the magnetic poles of the electromagnet are reversed and attracted to the other pole of the permanent magnet.

Changing the direction of the current repeatedly keeps a rotating.

How to work a motor (schematic view)

Frequency and Rotational Speed for AC Motors

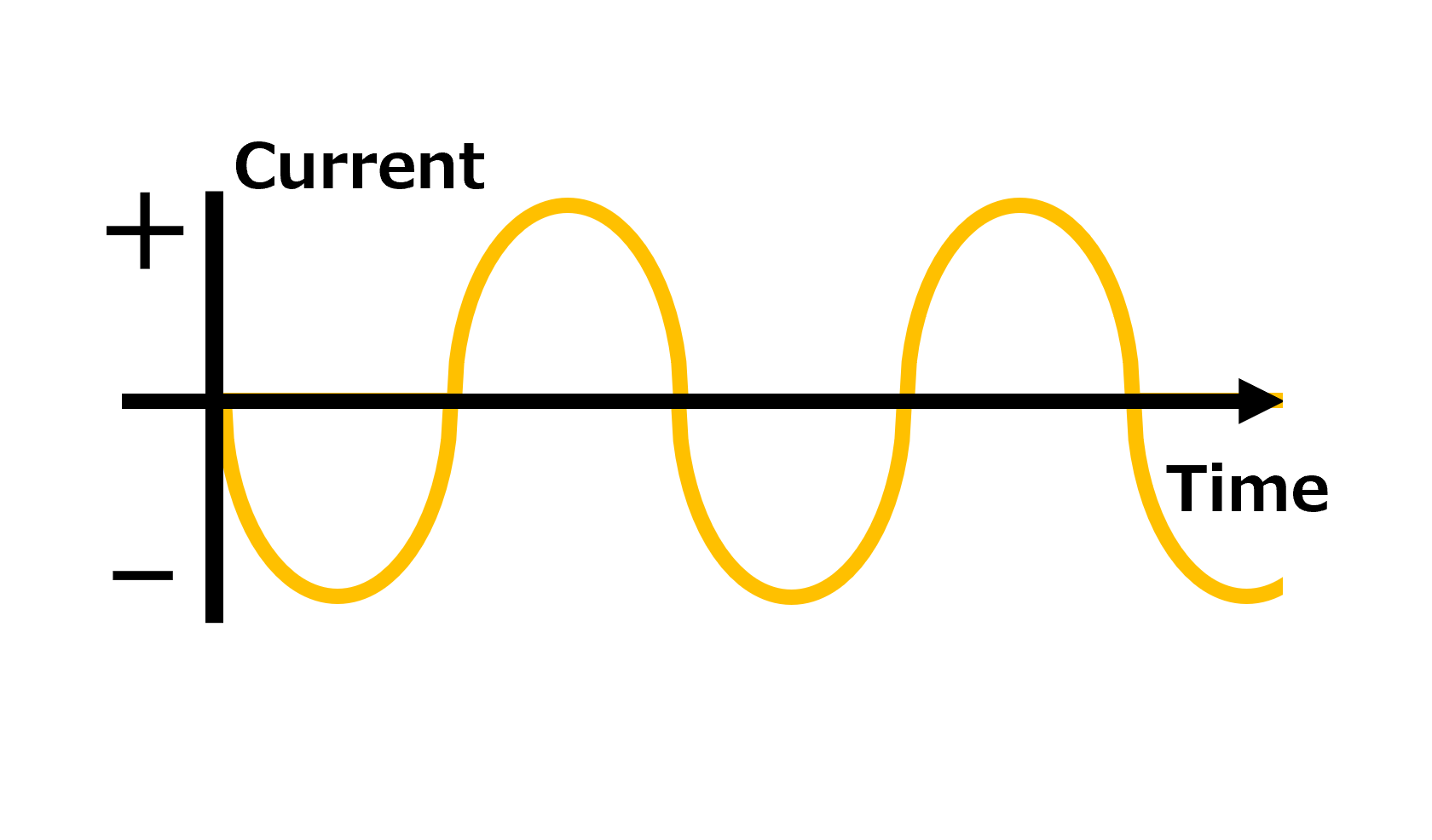

As described above, alternating the direction of the current between positive and negative keeps a motor rotating.

This current state is illustrated in the figure on the right.

In this way, current and voltage that change periodically in direction and strength are called alternating current (AC).

A motor is driven by AC.

On the other hand, current and voltage that remain unchanged in direction and strength are called direct current (DC).

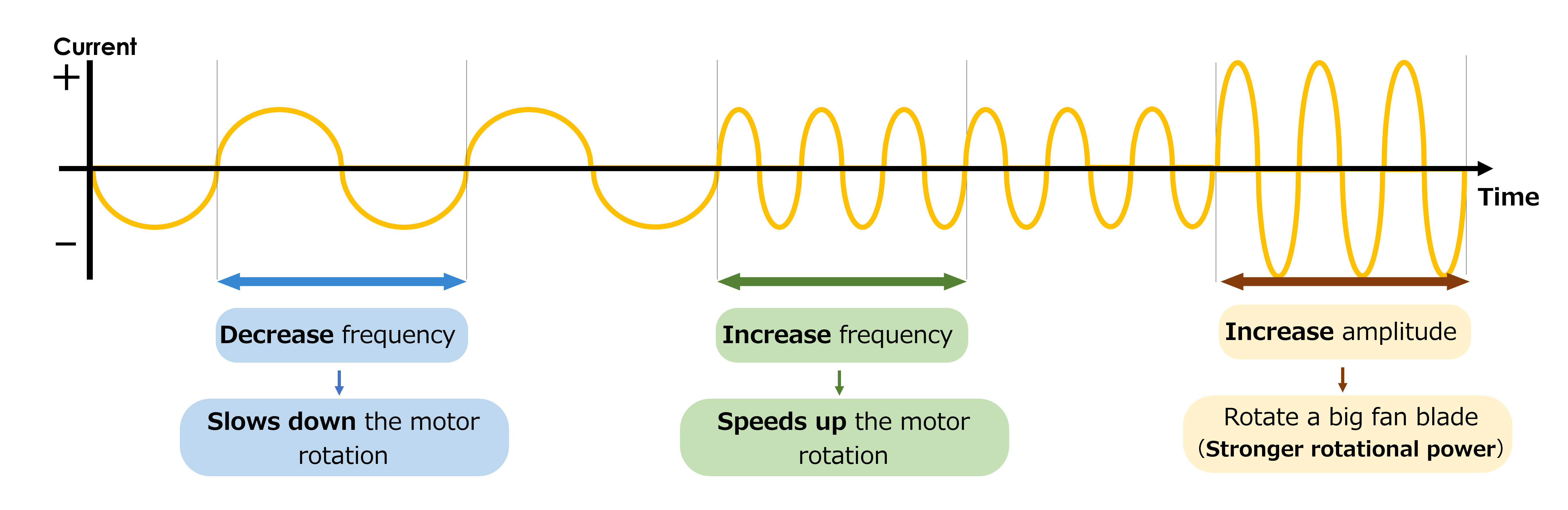

The number of times an AC waveform is repeated per second is called frequency. Increasing the frequency increases the rotational speed of the motor, and decreasing the frequency decreases its rotational speed.

Increasing the power allows a motor, such as a fan motor, to rotate larger blades.

Thus, by adjusting the frequency and amplitude of AC, the rotational speed and force of the motor can be controlled.

A semiconductor called a microcontroller controls the frequency and the amplitude.

The next part explains the control method in detail.

The Current Flow for Motor Rotation

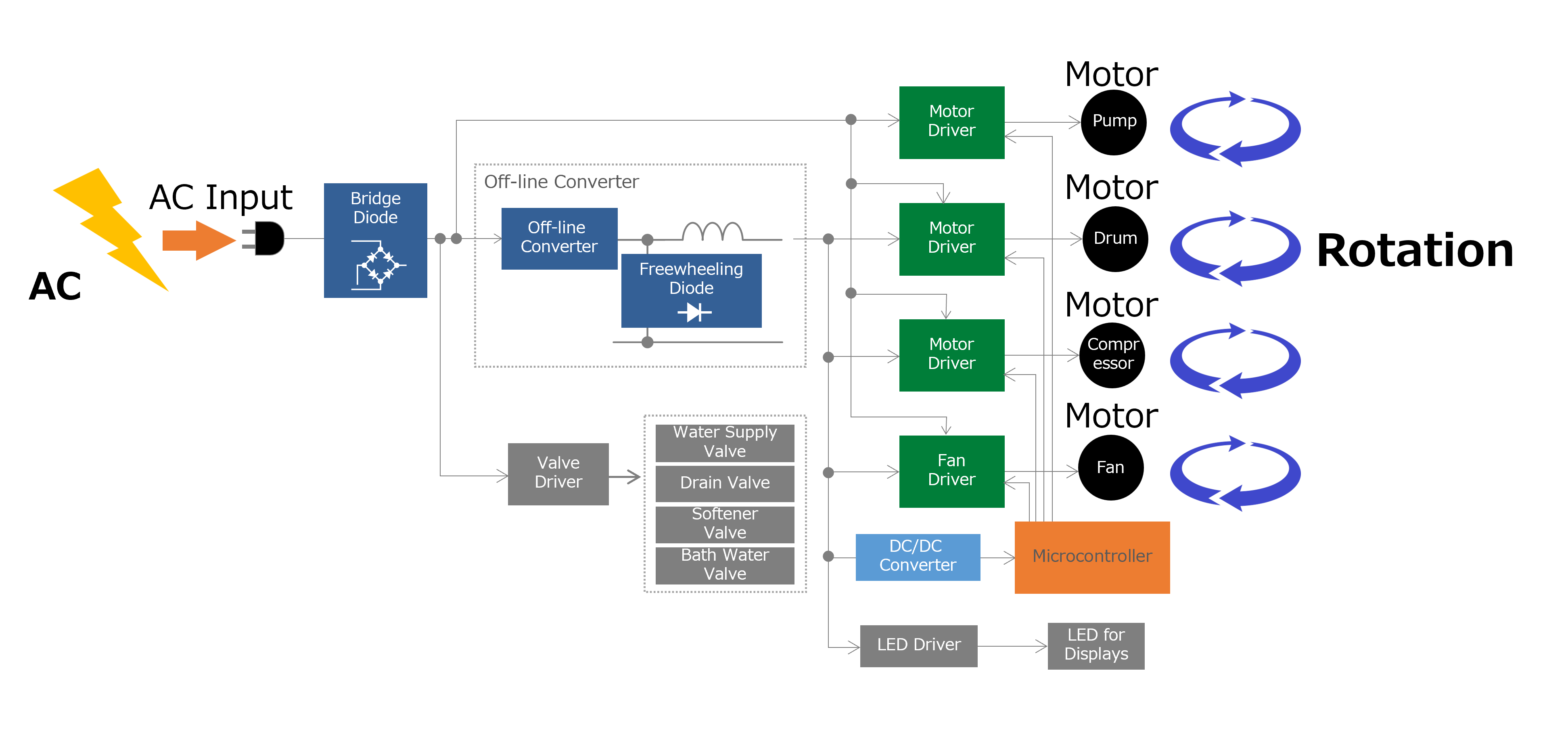

The block diagram below shows a configuration of a washing machine.

Motors are used in drums for washing tubs, water pumps for bathtubs, and compressors and fans in dryers to blow warm air.

Block Diagram of Washing Machine

The electricity flow to rotate the motors in a washing machine is as follows:

[Ⅰ] AC electricity is supplied from an outlet

The washing machine operates by plugging its power cord into an outlet. The electricity supplied from the outlet is AC, not DC.

[Ⅱ] Converting AC to DC

A motor runs on AC, but if the outlet's AC is supplied directly to the motors, the rotation speed and other controls cannot be managed, leading to wasteful electricity consumption. In applications such as washing machines, which consume relatively high power and require detailed control, "inverters" are used to convert AC to DC and then back to optimal AC.

Bridge diodes and AC/DC converters convert the outlet's AC to DC.

[Ⅲ] Adjusting the DC voltage

Next, the voltage is lowered by a DC/DC converter to supply electricity to the microcontroller, which is the command center that controls the motors.

[Ⅳ] The microcontroller sends commands to the motor drivers

The microcontroller follows precisely designed programs, and performs calculations and sends commands in response to user operations and signals from peripheral components.

For example:

・Rotate the drum appropriately according to the amount and type of laundry

・Stop the motor when an abnormal signal is detected

・Run the bath water pump to draw water up to the required amount

[Ⅴ] Motor drivers amplify commands and provide motors with them

The microcontroller is capable of performing extremely fast control and calculations, but the electrical energy that the microcontroller outputs is extremely small, so it is unable to drive motors by itself.

To solve this problem, the motor driver plays an active role in handling high power.

The motor driver amplifies the commands received from the microcontroller and sends them to the motor.

As explained above, the motor driver converts electrical energy into mechanical energy that moves the motor.

Current Flow to Rotate Motors

The Role of Motor Drivers

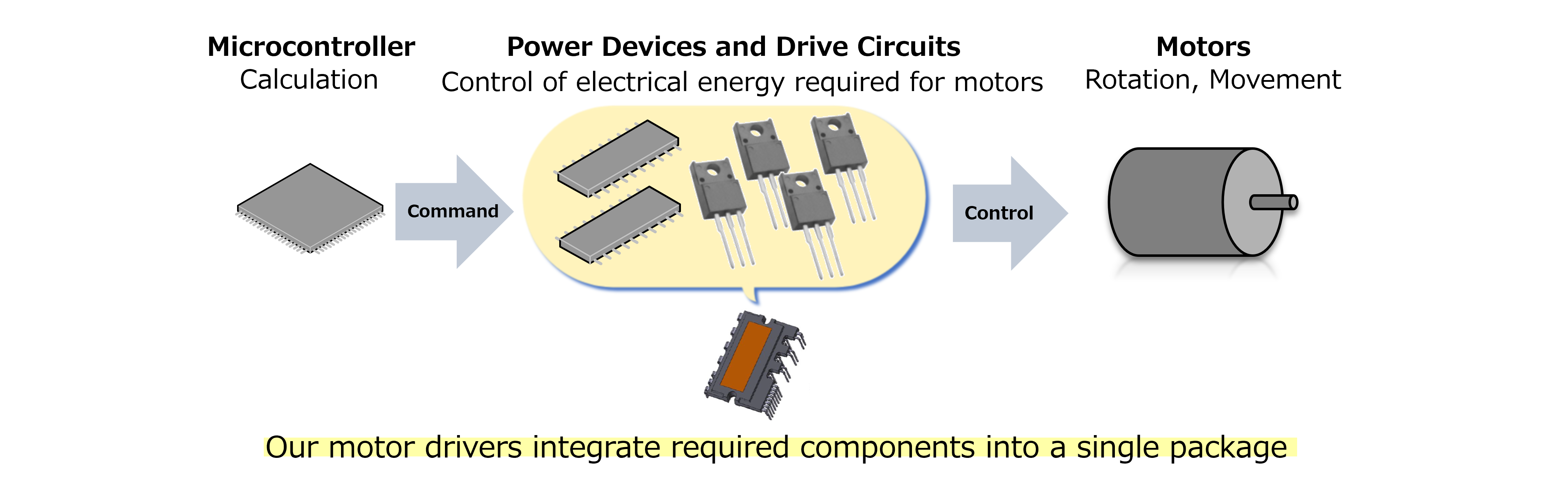

As its name suggests, a motor driver is a semiconductor product that is specialized for driving a motor.

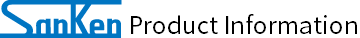

Our motor drivers integrate power semiconductor devices (e.g., power MOSFETs and IGBTs) and driver ICs for converting DC to AC and controlling the motor in a single package.

Using motor drivers enables the area of the mounting board to be reduced compared to arranging individual semiconductors, resulting in smaller products such as household appliances.

In addition, some motor drivers have added value features that detect abnormalities and enhance quietness, contributing to improved product safety and advanced functionality.

We have a broad lineup of advanced motor drivers that contribute to energy savings by improving the efficiency of built-in components and control methods.

Our motor drivers are used in various applications, including home appliances, such as washing machines and air conditioners, and xEVs (electric vehicles).

A board with a mounted motor driver

Various Motors and Their Features

The function required for a motor depends on the application.

Various types of motor drivers are available for different purposes, such as long life, high-speed rotation, and cost-effectiveness. You can choose the perfect motor driver that best suits your purpose.

| Supply Voltage | Lifetime | Position Feedback Control |

Types of Motors | Overview | Applications |

|---|---|---|---|---|---|

| DC | Over 10000 hours |

Necessary | Brushless DC Motors |

Sanken Electric's Brushless DC Motor Drivers ▶Intelligent Power Modules (IPMs) ▶Automotive Intelligent Power Modules (IPMs) ▶Automotive Motor Drivers |

Air conditioner, washing machine, refrigerator, electric vehicle (xEV), and more |

| Unnecessary | Stepper Motors (unipolar/bipolar) |

Sanken Electric's Stepper Motor Drivers ▶Low Voltage Stepper Motor Drivers (2-phase unipolar) |

Paper feed of printer, manufacturing equipment, arm control, and more |

||

| Less 10000 hours |

― | Brush DC Motors |

|

Radio controlled car, opening and closing of power side mirror, and more |

|

| AC | ― | ― | AC Motors |

|

Conveyor belt, blower fan, actuator, and more |

Questions or Comments?

Please feel free to contact us if you cannot find the desired product from the lineup.