3 Precautions for Packing

Please note that our semiconductor devices may be exposed to poor environments, including humidity and gas, depending on their packing conditions. This may result in deterioration in product quality and terminal solderability. Improper stress may also negatively affect our semiconductor devices, such as physical damage, ESD breakdown during unpacking operation, and so on.

3.2 Change of Storage Containers (Split across Storage Containers)

3.1 Storage Containers

For proper storage, please use our storage containers (e.g., stick magazines, trays, taping materials) that we used for shipping and delivery. However, our storage containers are not heat resistance. Please note that the stick magazines particularly made of polyvinyl chloride (PVC) material will soften at temperatures from 50 ℃ to 60 ℃.

3.2 Change of Storage Containers (Split across Storage Containers)

When transferring our semiconductor devices to other storage containers, please operate in an ESD-safe working environment. Moreover, our recommendation is to use antistatic storage containers that will prevent the semiconductor devices from any mechanical stress and chemical influence. Here are the guidelines you should consider and pay attention when transferring the semiconductor devices :

- Operate in a clean environment where no fiber waste is generated.

- Take ESD-proof measures during operation. See Section 9, “Measures for Electrostatic Discharge (ESD).”

- Wear conductive finger cots or gloves to prevent contamination and ESD breakdown. Be careful not to touch the terminal parts of the semiconductor devices your are transferring.

- Before transferring the semiconductor devices, check the following information again: part number, lot number, quantity, etc. This is to avoid any errors, such as putting different semiconductor devices mixed up into a container, or storing a wrong quantity of the semiconductor devices.

- For the semiconductor devices placed in a shield pack , transfer them in a short period of time, and then put the changed container into the shield pack again.

Example: Shield Pack for Through-hole Mount Devices

- For the semiconductor devices placed in a stick magazine, pay extreme attention to the orientation of insertion when transferring them into another stick magazine so that they will not be mounted on PCBs in a wrong orientation. Also, pay attention not to deform the terminals.

- For the stick magazines packed with the number of semiconductor devices below their maximum quantities , fill in the internal empty space with cushioning material (e.g., a conductive sponge) to stabilize the semiconductor devices.

- After transferring the semiconductor devices, check the terminals again whether they are deformed or not. Also, make sure that the original storage container is empty and there is no semiconductor device left inside.

- Hall ICs are specially structured with built-in magnets. If you need to change the storage containers used for our Hall ICs or hall-effect devices (or to split the devices across multiple storage containers), please contact us for more information.

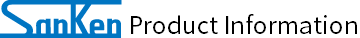

Example: Deformed Terminals

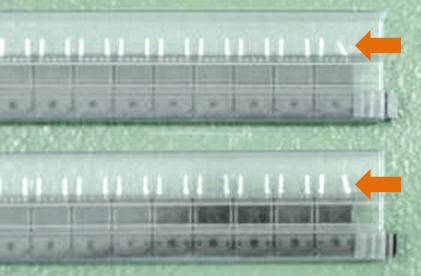

Example: A Device Incorrectly Mixed Up into Stick Magazine

3.3 Moisture-proof Packing

For the semiconductor devices packed in moisture-barrier materials, please do not transfer them from the original containers to other ones. Also, please be careful not to create any hole on laminated or plastic bags.

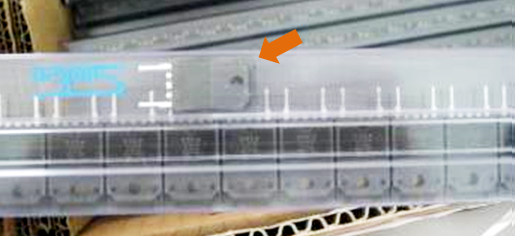

Example: Moisture-proof Packing

3.4 Packing Materials

For the materials that you consider using after changing containers (e.g., stick magazines, plastic bags, corrugated boxes, packings, inks, tapes, labels), please be sure to use the materials we supplied or specified. If you use materials other than those, it is your sole responsibility to manage all the substances contained in your packing materials for compliance with the laws and regulations on specified hazardous substances (product environmental quality).

Questions or Comments?

Please feel free to contact us if you cannot find the desired product from the lineup.